Well, it is probably about time I introduced myself.

My name is Al, am one of the mods around here to give Trav a hand with things, have been following his nEfi project for a couple of years.

I am a qualified auto electrician, working in the mining industry, predominately in the underground heavy fleet, on loaders and trucks that weigh around 60 tons unladen.

During my time off of work, when not being harassed by the wife and kids, I like to fix/repair/modify, I cant help myself, standard is for chumps.

Manufacturers have to build things to meet emissions and noise standards, maximize profit, etc.

Tech has advanced a long way since some of the machines here were built, parts (IE carbs) have worn, and some parts might not even be available anymore.

I was living in Mt Isa, North West Queensland, Australia, with a tropical to sub tropical climate, which would vary from a dry winter to a hot and humid summer, so air/fuel ratios would be constantly changing.

At the end of 2019, I moved back to Adelaide, in South Australia, where the climate is totally different (Cold wet winter, hot dry summer)

I was looking around for an efi system, that would fit relatively easily, and be reliable, I came across a couple, but they just seemed ‘clunky’, with the possibility of being unreliable and not really fitting the bill.

I started to rebuild this bike, and got a larger carby for it off a 500cc, but then came across the nanoEFI while still in its early stages.

The engine has been rebuilt and is now a 425, hence the bigger carb.

Bike is kickstart, but I have got a AA battery pack to fit to it, as this would help smooth out any voltage fluctuations it had, ie at idle.

Now that nanoEFI is coming along, it will double as a power source to power the fuel pump for priming and power for the EFI controller.

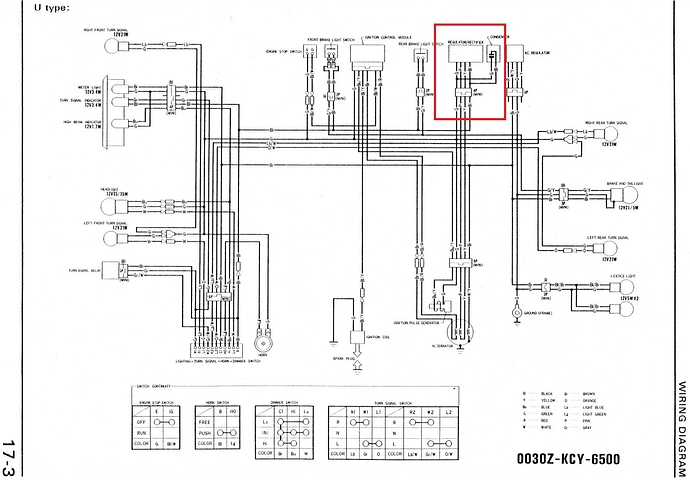

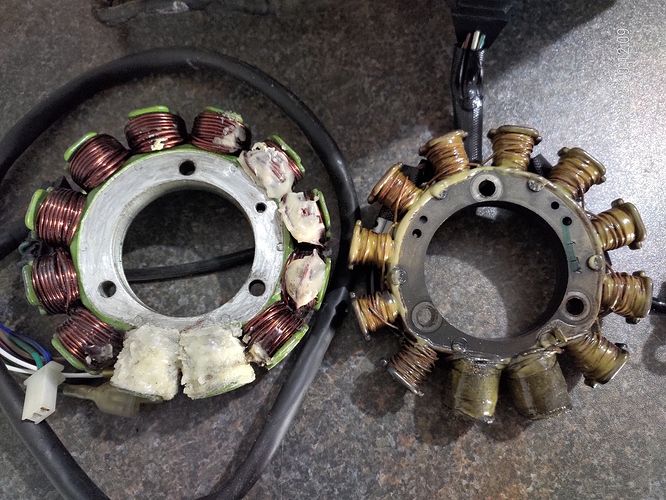

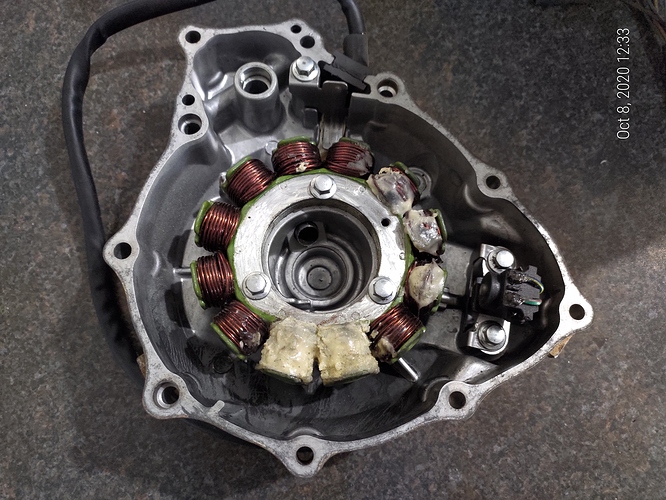

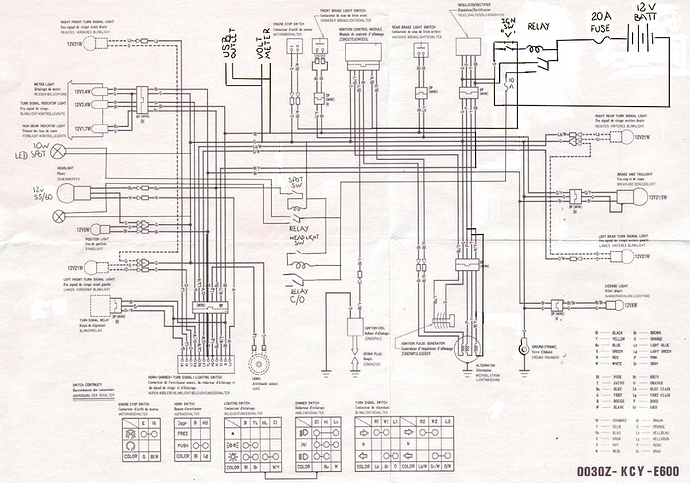

Another upgrade is a fully wound stator and new rectifier to cope with it.

The bike is pulled down, as I was living on the other side of the country, so it will take some time until it is reassembled.

The sad state it looked in when I purchased it cheap off a mate.

My aim is to build it to look similar to this.