Went well!

Started assembling the board. Looks like I rode hard and put the stencil up wet last time. No problem, just cleaned it up with some alcohol to remove the old dried solder paste.

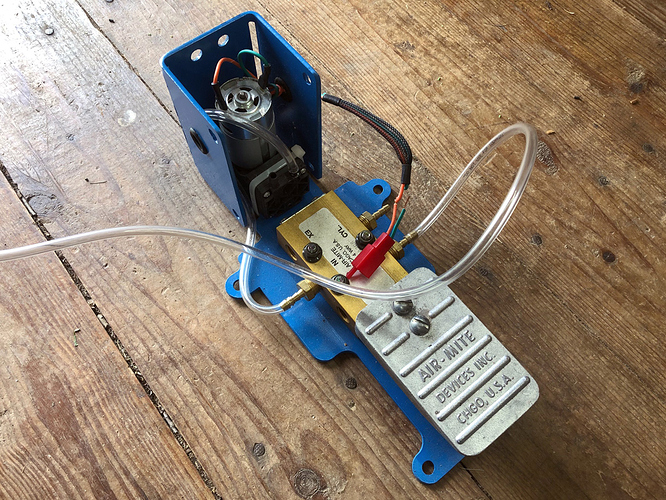

Manual vacuum picker had some damage to the leads. Fixed that up without further incident.

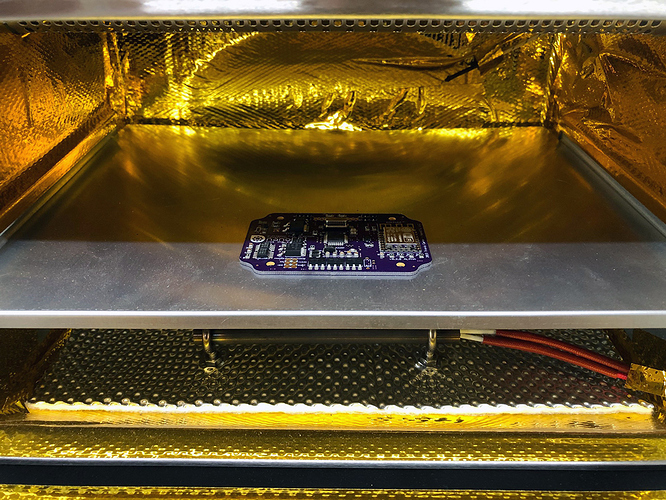

Assembled the board in about an hour and threw it in the oven. Just like baking cookies.

The reflow takes 13 minutes to complete, so I went out to the Ranger to figure on the harness for a bit. I was interrupted by this enormous “giant” stag beetle. Big bastard.

I think he was just looking to help pick and placing those board components. Had to let him know he just missed the party.

I had the sudden urge to 86 the Ranger and everything around it entirely. But before I could act, I took two steps to the left and was greeted by an Eastern Kingsnake passing through.

Left his card and told me to call when I’m ready for the wire tuck…

Iano tho… I think I’ll manage

After getting distracted by the local wildlife, the board was done cooking but still needed to cool down. Decided to grab a quick snack.

Yum

I ever mention I’m country AF? Now ya’ know.

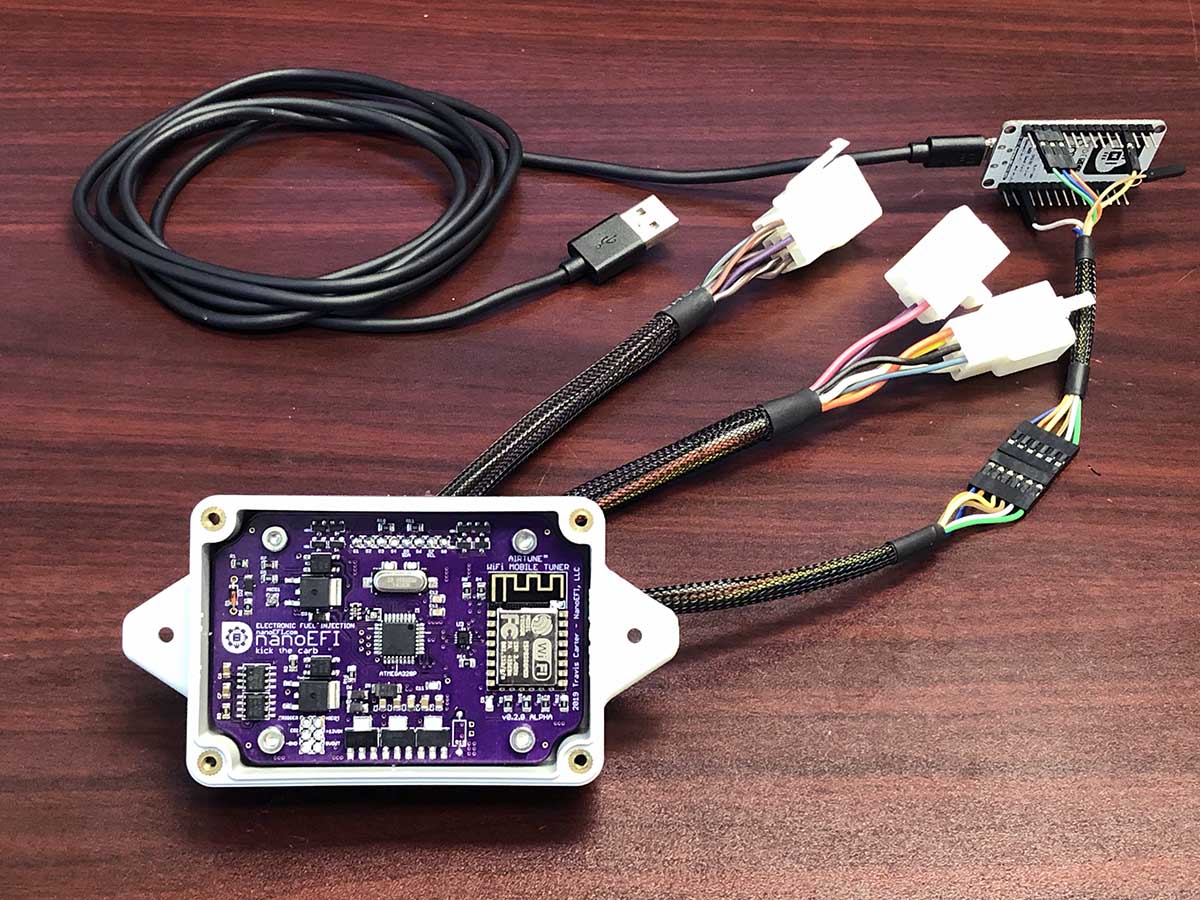

Alright, here we go. Cleaned up the board. Inspected each solder joint. All good except the resistor network for the RGB LED. Fixed that, and bagged it up. It had a few other thing to get done Saturday, so this is how it sat overnight.

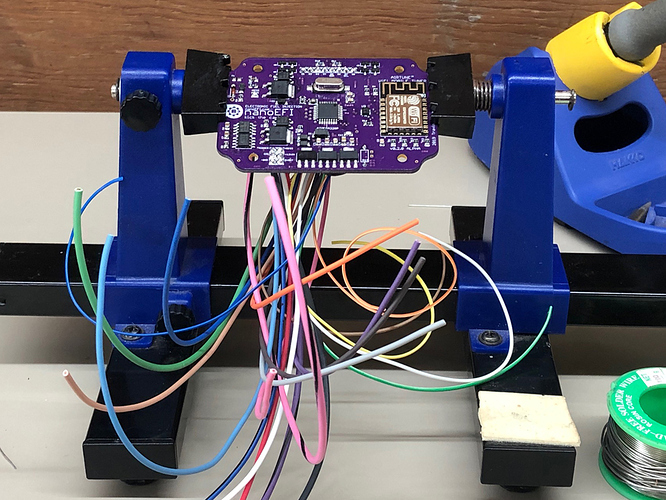

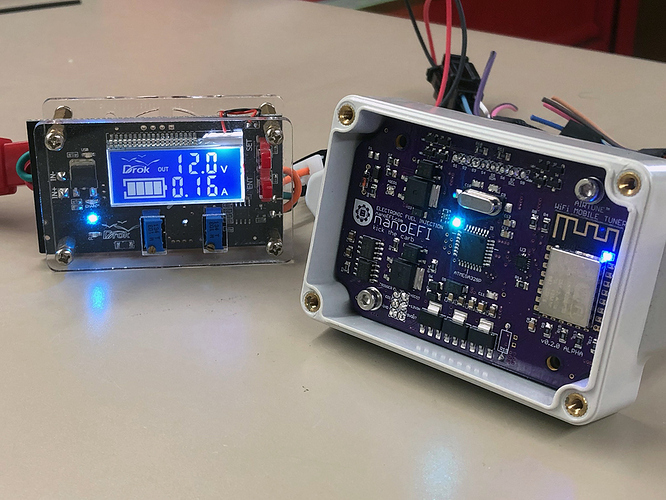

Sunday afternoon. Attached all the wire leads, which is not my favorite part of the process. Takes way longer than it should. But I won’t have to deal with this on the next board version fortunately.

I forgot to take pics at this point, here are a couple from the last board.

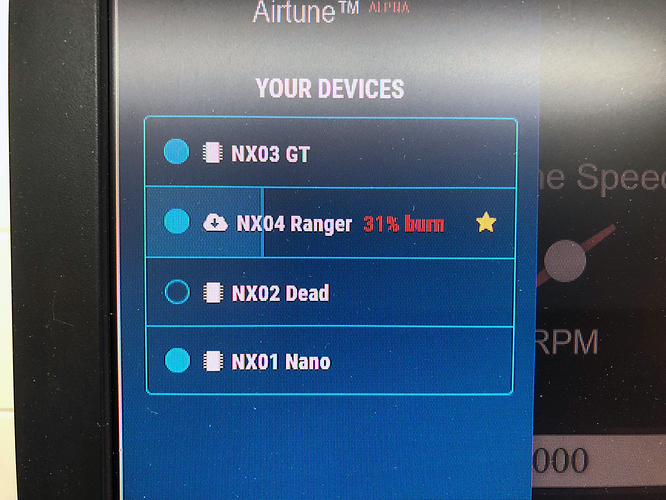

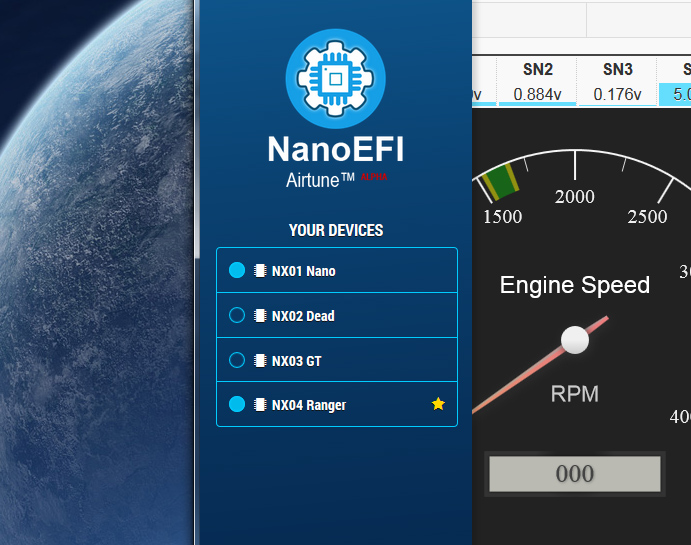

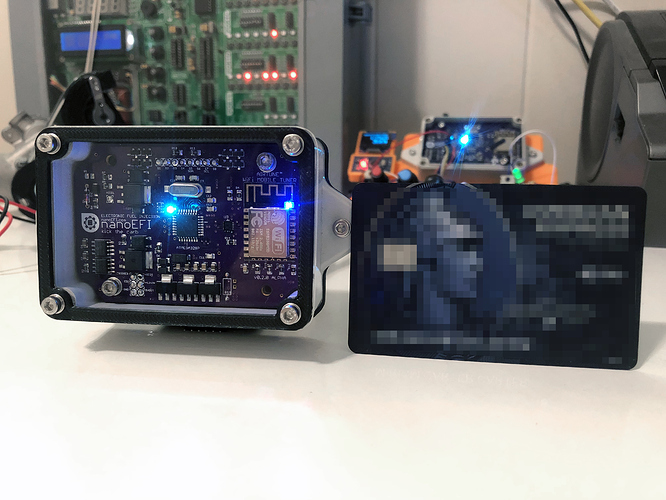

Now we’re making progress. Flashed the onboard tuner co-processor and registered the device to my account online in Airtune. Connected online within just a few seconds.

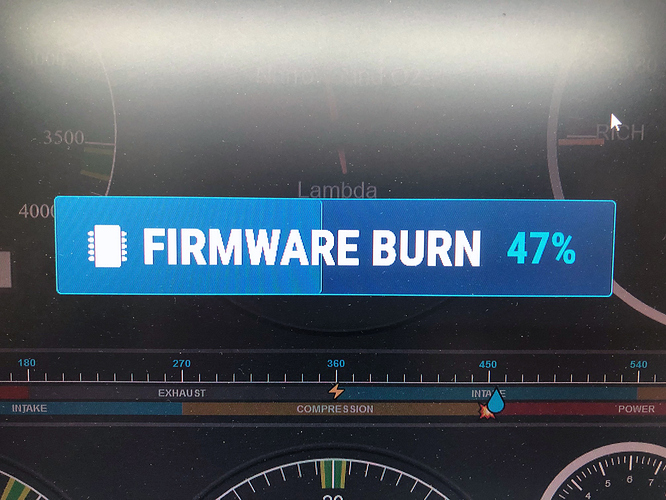

The the very last step… flashing the main processor over OTA. It’s the moment of truth…

Will it live?

Yes!

Took an extra minute to fix alphabetical sort for registered devices in Airtune.

10 points to Gryffindor for anyone who gets the NX reference.